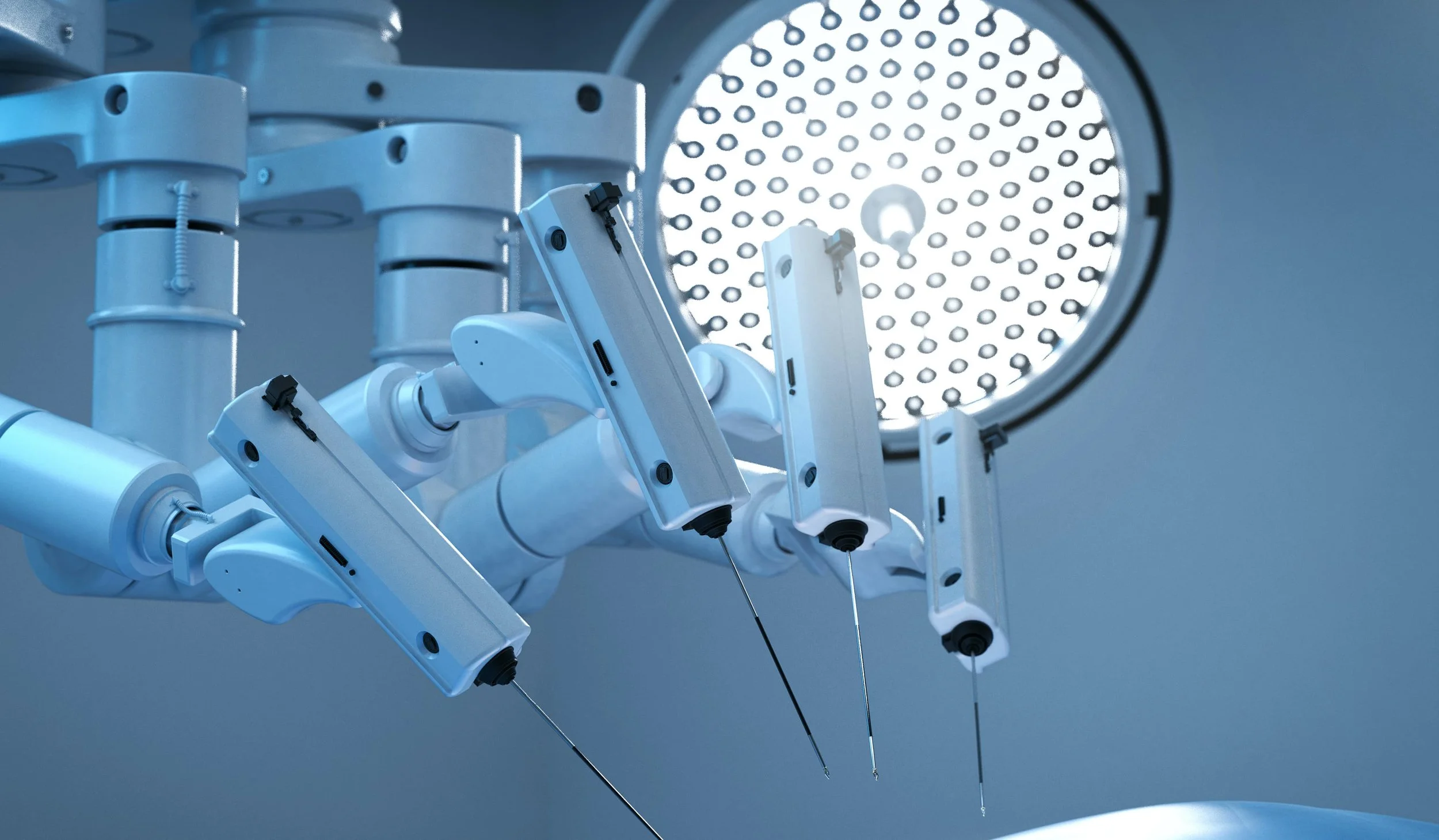

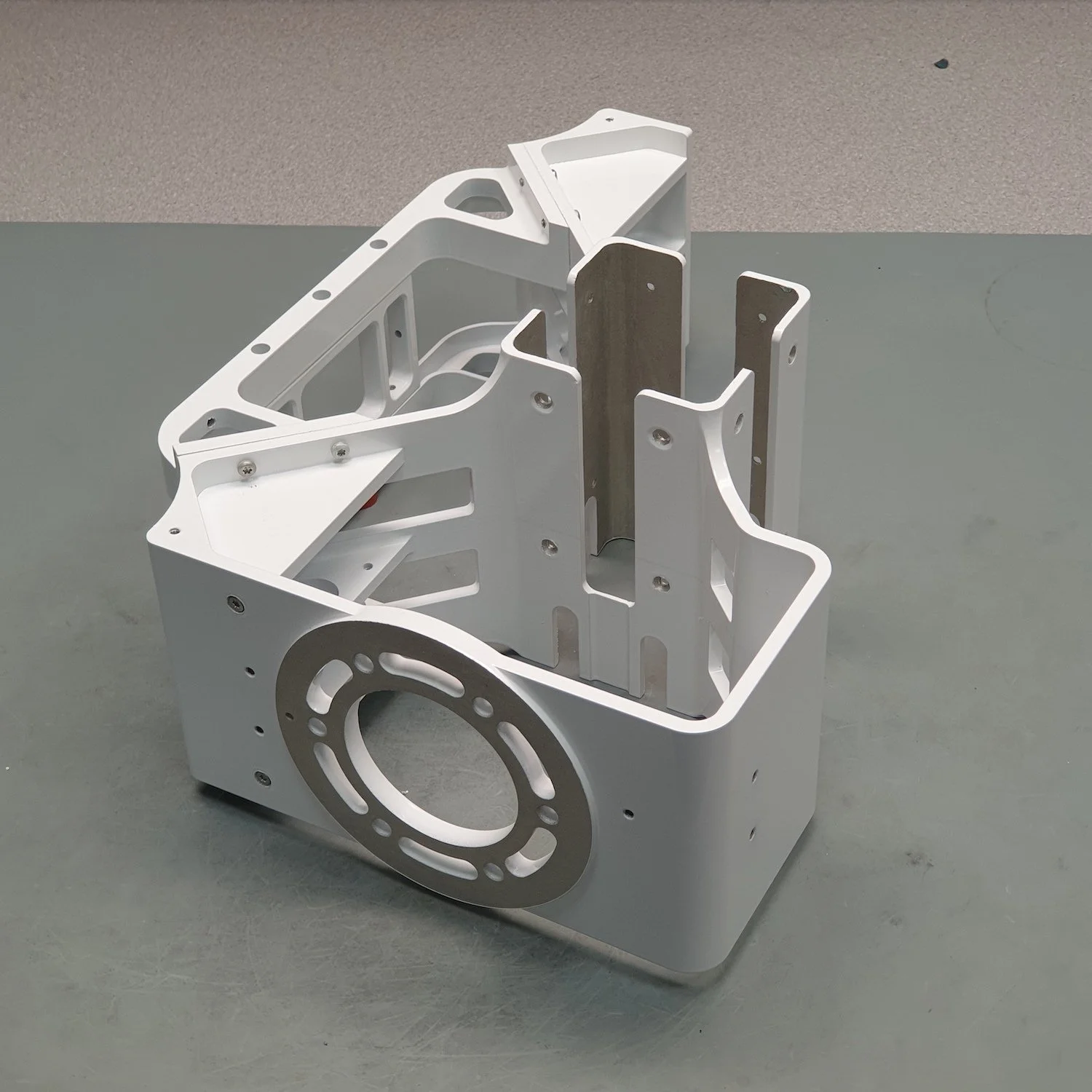

Powder coating for medical equipment - smooth, clean, precise

At Powdertech masking for powder coating and powder coating services for these intricate and complex components are handled in a room separated for this purpose.

The health sector demands reliable, consistent and durable surface treatments for machined medical devices and installations, one that we have been proudly delivering to our clients for over ten years. We use chromate-free TiZr passivation to enhance coating durability together with high performance powder coatings.

Powder coatings are a dry powder and emit zero or negligible volatile organic compounds (VOCs). They contain no halogens or heavy metals and conform to the reaction to fire rating A2-s1,d0. This finish is very easy to clean, an essential attribute for this sector.

““High quality of finished product and excellent reliable turnaround. And, very importantly, they listen. ””