News & insights

Critical joining knowledge

Titanic, Belfast on March 21st 2019 - JOINING OF COMPOSITES CONFERENCE . Don’t miss a highly instructive, educational showcase for recent international developments in composite joining. Powdertech Surface Science will be presenting PowderBond, our new technique for bonding composite to metal without the need for a separate adhesive.

Fourteen short presentations from key players in the field will ensure that you are thoroughly updated on the latest in composite joining.

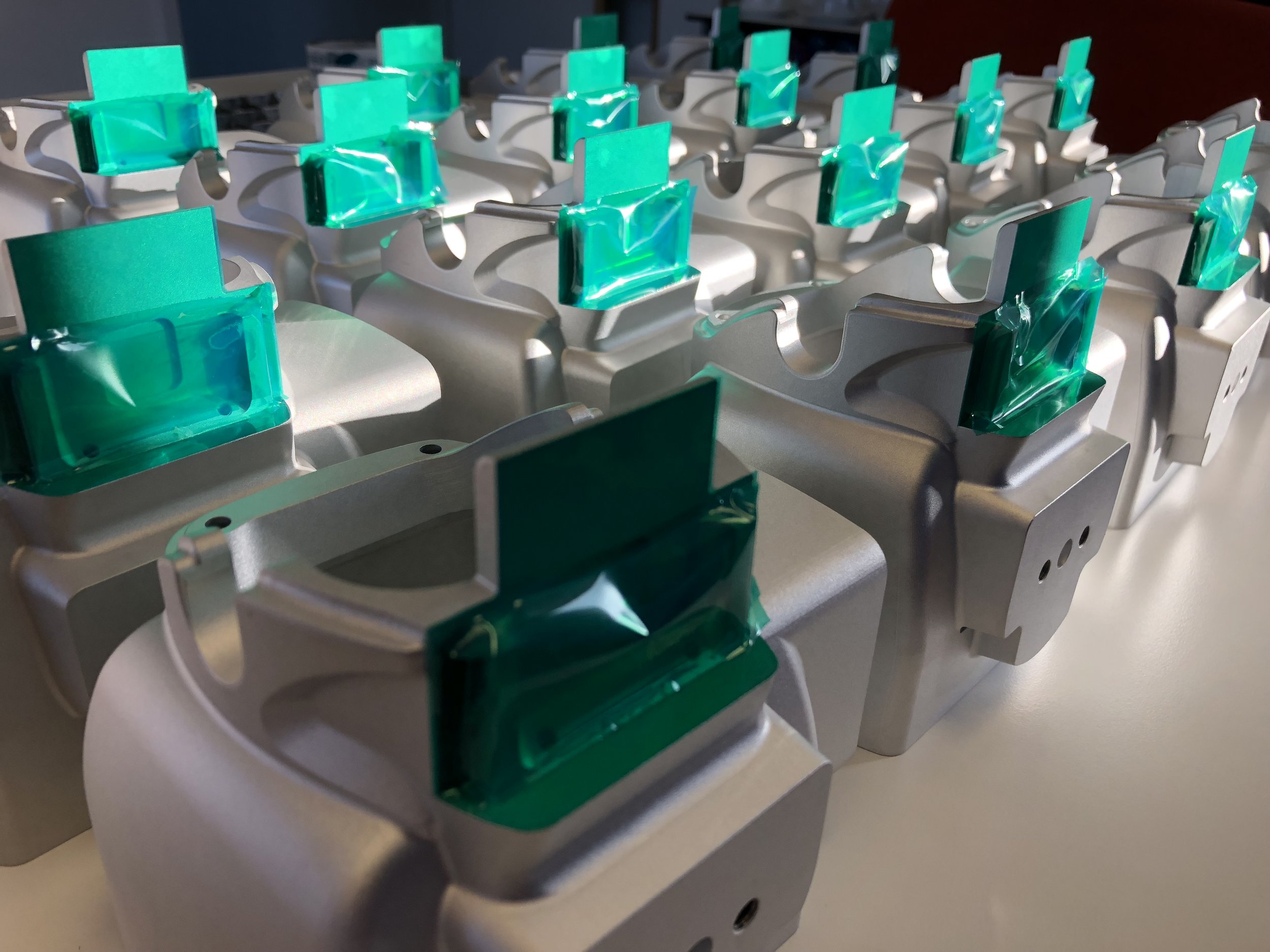

Our latest service - Iridite NCP latest service

We have added Iridite NCP to our range of chrome-free coating systems. This chrome-free conversion coating is frequently specified by regulated industries due to its special properties. Powdertech Surface Science has been operating chrome-free treatments since 2001 when the company was the first powder coater in the UK to go chrome-free so you can be confident that your components are in very safe hands.

Medical equipment coated in Iridite NCP

Smart transport

We are delighted with our brand new lorry, complete with smartly designed curtains.

Customers’ items can be collected and delivered even more efficiently because this new vehicle can carry more weight and a greater length of material.

Meticulous coating

The precision and attention to detail of our coating system has been used to great effect in a set of contemporary dining chairs for Sebastian Blakeley, London-based bespoke furniture designer. Each chair is tailored to the client’s requirements in terms of wood and aluminium finish. Powdertech Surface Science coated the fine, uniquely shaped aluminium legs for a set of eight chairs, in matt black, contrasting beautifully with the polished aluminium and dark wood. Those areas where coating was not required were carefully masked. The chair design is ‘Màntide’ – meaning ‘praying mantis’ – the inspiration for the shape and form of the chair

Vacancy for a Management Trainee

Junior Production Manager/Management Trainee

The Role

As a result of continued success and as part of an ongoing programme of strategic growth, we are now seeking to recruit an enthusiastic, self-motivated and intelligent Junior Manufacturing professional to complement our highly successful team and embark on an exciting training and development programme to become a Production Manager of the future.

The successful candidate will:

· Learn all areas of the business through a structured training schedule

· Gain exposure to all facets of the operation, from hands on working in each of the production areas to time spent in the production planning and logistics functions

· Receive business improvement training from an external provider which supports our lean manufacturing principles.

You will be following in the ranks of others who have successfully completed the same training programme and now hold senior positions across the business.

Requirements

Whilst dedicated surface treatment sector experience is not required, it is envisaged that you will be qualified to degree level, or equivalent, and have at least 2 years’ business experience ideally gained within an engineering, manufacturing or technical environment.

You will thrive on a varied and fast moving production environment, which will provide challenges for you to understand and overcome. You will be rewarded for your achievements and recognised for making a difference. This is a great opportunity to join a growing SME, and one that is market-leading in its field.

Location

The applicant will need to live, or be prepared to re-locate, within commutable distance of the office in Bicester, Oxfordshire.

Benefits

Salary 25k-30k depending on experience. Pension. 24 days holiday

Enhancing treatment control through investment in new pre-treatment pilot line

As a leading industry expert in the surface treatment of lightweight materials, PSS needs to provide a quick response to customers' requests. We have invested in a new pre-treatment pilot line that allows us to run small volume prototype or production work, away from the main pre-treatment lines, and trial new processes quickly and easily. Crucially, this facility puts us in control of each stage of the treatment process. Overseen by our PhD qualified staff, we can help customers solve their surface treatment issues quickly and efficiently.

PowderBond to be presented at an exclusive event at the Electrolux Innovation Factory in Italy.

25th Oct 2018 PRESS RELEASE : On 30 October, a selected group of companies funded by the European Innovation Council (EIC) pilot will present their solutions to Electrolux at the Innovation Factory, a collaborative space which serves as the Electrolux Group’s hub for innovation with external partners. Powdertech Surface Science was one of the 14 companies selected to attend this exclusive event.

Located at Electrolux manufacturing site in Porcia, northern Italy, the Electrolux Innovation Factory facilitates alliances between suppliers, customers, incubators, startups, universities, SMEs, and other business partners to accelerate innovation projects. The facility also includes demonstration and test areas for both product and process solutions.

Powdertech Surface Science will have the opportunity to share its visions and showcase its innovations in the field of composite/metal bonding to Electrolux managers and to network with fellow SMEs.

“We are very pleased to be selected for this EIC pilot event as we believe that PowderBond, our metal/composite bonding solution, offers exciting development opportunities for Electrolux. The event will provide us with an excellent basis for discussing how PowderBond could bring significant benefits to this forward- thinking company. ” said James Grant, Director, Powdertech Surface Science.

The initiative will be hosted by Electrolux Open Innovation, whose purpose is to identify new business opportunities across the entire value chain of the company and support the transformation of external innovation into tangible solutions for the company.

The principles of Open Innovation underlined by Electrolux, are aligned with one of the objectives of the EIC pilot: to support active collaboration between innovative small companies and large corporates. “The EIC should be the link between the start-ups and the corporates. By helping start-ups to access partners across value chains. From corporates to investors… and technology providers. At the same time large, corporates should be able to help start-ups to scale-up.”, said in a recent speech, Carlos Moedas, European Commissioner for Research, Science and Innovation.

PowderBond at EIC Pilot Corporate Day, Solvay, Brussels

“Open innovation - the potential to move mountains”

We were very pleased to be invited to pitch at the EIC Pilot Corporate Day, October 16th, 2018, at Solvay, the advanced materials and speciality chemicals company. This was a business acceleration event aimed at SMEs working on breakthrough innovations. Our recent launch of PowderBond, a bonding solution for metal to plastic, prompted the organisers to select Powdertech Surface Science as one of 22 companies to pitch products and services judged to be relevant to and aligned with Solvay’s business strategy.

Condensing the features and far reaching benefits of PowderBond into a six-minute pitch was a challenging but worthwhile experience. The event provided valuable networking opportunities with Solvay managers, partners of Solvay and other presenters.

To quote Stéphane Roussel, Solvay Ventures Managing Director

“Open innovation is all about finding mutual interest to work together. A well-defined purpose and clarified roles and responsibilities are key conditions to success. On one side: size, scale, credibility; On the other: agility, creativity, and speed. The combination has the potential to move mountains.”

PowderBond - At Thermoplastic Composites 2018, BPF House, London, October 4th.

Demonstrated as a proven technology in the Ariel Hipercar project, Powdertech’s innovative adhesive-free bonding process, PowderBond, is creating a great deal of interest in the industry. Powdertech Surface Science Technical Consultant, Dr. Nick Welton, will be presenting details of the process and how it was used in the Ariel Hipercar project, at Thermoplastic Composites on October 4th 2018 in London.

PowderBond offers significant advantages to anyone bonding plastics to metal. Not only are there clear business benefits arising from absence of adhesive in the process, but the resulting bond between the metal and the plastic proves to be stronger than that using traditional methods.

“PowderBond is at the fore-front of material surface technology “ said Dr Welton, “At Powdertech Surface Science we strive to use the inherent surface properties of materials to improve manufacturing processes in all aspects – swifter production, less wastage, less energy consumption and improved quality of product."

The conference showcases the latest technical advances in thermoplastic composites and is a joint Composites UK and British Plastics Federation event.

Register online at http://www.bpf.co.uk/events/thermoplastic-composites-2018.aspx

See our PowderBond page https://www.powdertech.co.uk/powderbond/

A time-saving in-mould method for metal/composite hybrid assemblies

In many manufacturing industries, two dissimilar lightweight materials, such as a metal and a composite or plastic, need to be strongly bonded together in order to form a hybrid assembly, providing strength and flexibility. The metal will be coated for corrosion protection and both materials will undergo physical changes as part of the moulding procedure. Rather than introduce a third material - an adhesive - wouldn’t it be simpler if bonding could occur during the moulding process as a consequence of the physical properties of the materials?

PowderBond does just that. The coated metal component and composite material are placed together in the moulding system and a strong bond is formed between the materials during the normal composite forming cycle. Heat at the material interface creates the bond, fusing the parts together.

This makes for an extremely lean manufacturing process, with significant savings in time over traditional adhesive bonding methods.

There is no need to spend time preparing the composite surface, which may have required transportation to an off-site treatment facility. No time spent checking the surface activation level and no time constraint set by a limited surface activation time. Once the composite part has finished its forming cycle there is no need to spend time applying adhesive, clamping the parts together, and waiting for the adhesive to set. Using PowderBond, the metal and composite leave the mould together, already strongly bonded with up to three times the bond strength achieved with adhesives. There is no need for mechanical fixings and no risk of fibre breakage in the composite.

PowderBond is an innovative bonding process developed by Powdertech Surface Science. At the fore-front of material surface technology, we strive to use the inherent surface properties of materials to improve manufacturing processes in all aspects – swifter production, less wastage, less energy consumption, improved quality of product.

Powdertech and magnesium go back a long way

Magnesium is 33% lighter than aluminium, 60% lighter than titanium and 75% lighter than steel with excellent elongation and ductility properties. Industry observers anticipate a resurgence in its use through the 21st Century as it has great benefits to offer as a structural material.

A lot of the demand is emerging from automobile and aerospace manufacturers who are increasingly shifting towards magnesium-alloys to reduce vehicle and aircraft weights and meet growing fuel-efficiency demands. There is an abundant supply - magnesium is 4th most common element in the Earth (after iron, oxygen and silicon) and it is 100% recyclable.

Corrosion resistance is critical and die cast magnesium components can be powder coated or e-coated. Powdertech Surface Science has been powder coating magnesium for over ten years, operating all large automotive OEM approved magnesium chrome-free pre-treatment systems. For aerospace-approved magnesium alloys to class L (with top coat) or class S (no top coat) specification we use Gardobond X4729 eleven-stage chrome-free pre-treatment.

ISO 9001:2015

Powdertech Surface Science has a proactive approach to quality management. We are pleased to have achieved the revised standard ISO 9001:2015, demonstrating our commitment to systems which ensure that our powder coating and material bonding services meet the high performance levels demanded by customer, statutory and regulatory needs, and will be continuously improved.

Powder coating this year - maybe PowderBond next year?

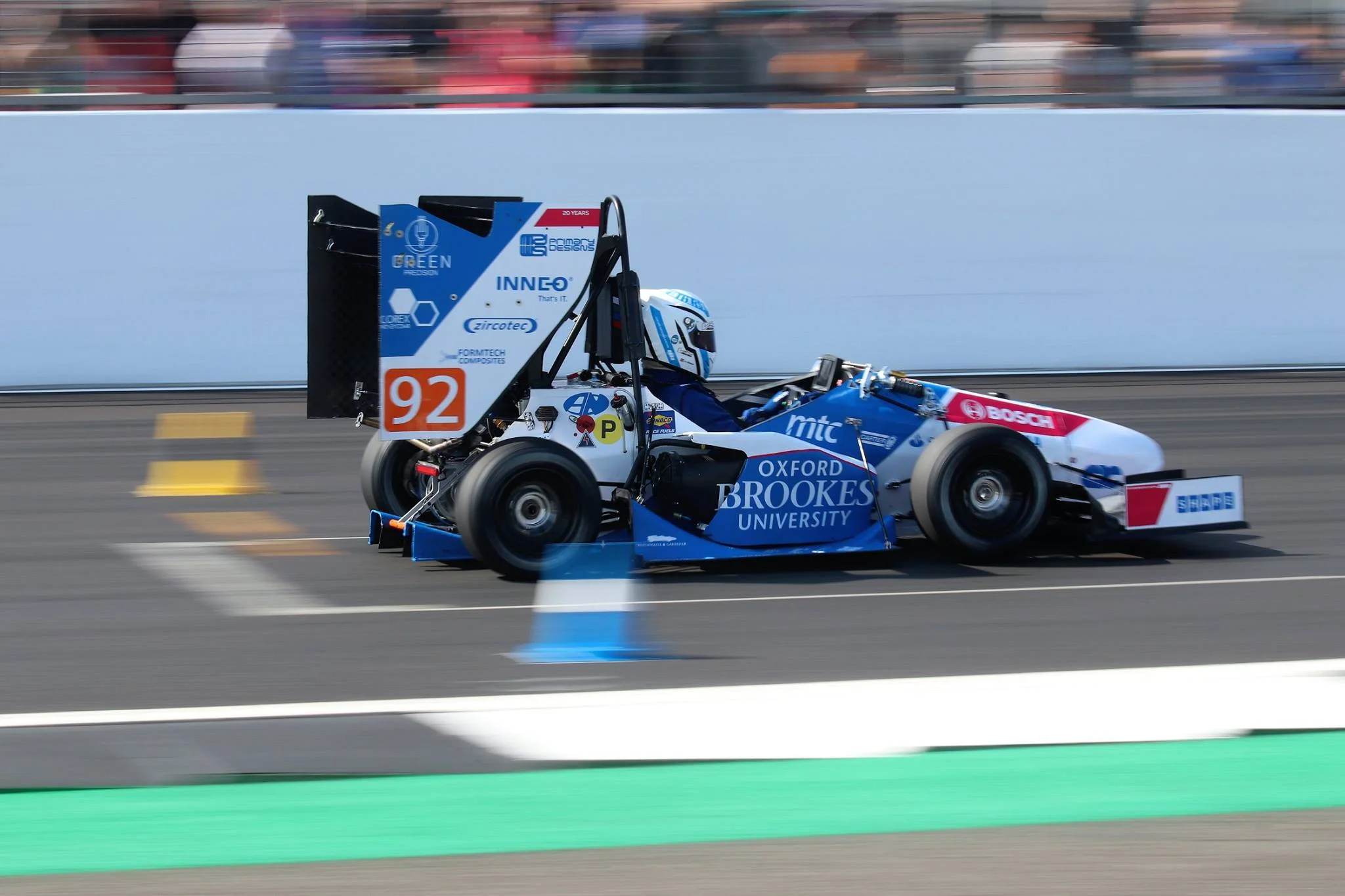

Many congratulations to Oxford Brookes Racing - the top UK team at FSUK 2018, and a well-deserved second place on the Silverstone Circuit in July. We were delighted to offer our powder coating services and wish the team continuing success. If adhesive-free bonding of lightweight metals and composite materials is an option for Frankie’s successor we’d be happy to discuss Powderbond.

PowderBond hits the headlines in CiM

We were really pleased to be interviewed by the journal and to explain more about our innovative, adhesive-free bonding process for composite-to-metal.

PowderBondPP – Officially launched

PowderBondPP – Bonding aluminium to polypropylene without adhesive

Available now, our innovative bonding process is already creating a great deal of interest in the industry.

New adhesive-free metal-composite joining process

Powdertech Surface Science Ltd has developed an innovative, time and labour-saving method for joining metal to thermoplastic composites. Demonstrated within the Ariel Hipercar project, adhesive-free Powderbond™ bonds polypropylene glass fibre composite to aluminium in the vehicle’s monocoque chassis. The process is single stage, placing powder coated aluminium into a mold together with polypropylene and using the standard composite curing cycle. No adhesives are used at all.

Powdertech Surface Science Ltd has developed an innovative, time and labour-saving method for joining metal to thermoplastic composites. Demonstrated within the Ariel Hipercar project, adhesive-free Powderbond™ bonds polypropylene glass fibre composite to aluminium in the vehicle’s monocoque chassis. The process is single stage, placing powder coated aluminium into a mold together with polypropylene and using the standard composite curing cycle. No adhesives are used at all.

Powdertech’s work was part of the SOLMAC project, funded by the Niche Vehicle Network as one its Production Readiness projects and supported by Innovate UK, OLEV and the APC.

Lean manufacturing

“We are delighted with the result”, said Simon Saunders, founder of Ariel Motor Company. “The process is clean and quick, and the bond strength achieved far surpasses current adhesive-based methods”. This is a lean manufacturing process with no surface preparation necessary for the polymer, no activation period and an energy saving short curing cycle. A typical chassis is made up of several hundred separate parts, welded and riveted together. By creating the aluminium-composite bonds within a mold, the number of parts in the Hipercar chassis is reduced by over seventy five percent.

Design flexibility

“Bonding metals and composites in a single stage gives tremendous freedom in design” said James Grant, Powdertech Director. “Complex and intricate shapes can be moulded into the composite structure whilst also incorporating high strength metal features. Powderbond™ makes it possible, today, to use the best possible lightweight materials for the job, exactly where they are needed.”

We would be delighted to discuss the wide-ranging implications of adhesive-free Powderbond™ with anyone who is joining lightweight metals to composite materials. Please call on 01869 248218 or email us.

More about Powderbond on our Projects Page.

The chrome free timeline explained.

There is lots of talk about going “chrome free” in our industry, although we at Powdertech Surface Science in Bicester have been using completely chrome free coating processes for over 16 years now, we thought we would take a brief look at what the EU has done to reduce the use of chromium in general.

Now, we have made a snazzy timeline to highlight some key dates but let’s look at each date with a little more detail:

September 2000 – Directive 2000/53/EC End of Life of Vehicle

The European Commission estimated that end-of-life vehicles (ELV) generate between 7 and 8 million tonnes of waste in the European Union per year. This directive was created to set clear targets for the reuse, recycling, and recovery of the ELVs and their components in order to make recycling said vehicles easier. It also aimed at making manufacturers create vehicles using more environmentally friendly materials excluding the use identified hazardous materials including lead, mercury, cadmium, and hexavalent chromium or chrome VI.

The ELV Directive was reviewed or subject to a “fitness check in 2014”

May 2001 – Powdertech Surface Science goes chrome-free

Due to local legislation and our move into the automotive sector we decided to install a chrome free pre-treatment line and remove our chrome processes altogether. This meant improving and simplifying our waste management but also reduced our chances of contamination. We opted for a new technology at the time; a titanium zirconium based chemistry.

The process has now been running for over 15 years applying passivisation for bonding and powder coating to all types of aluminium and magnesium. Since the inception of our chrome-free treatments we have been constantly making improvements as our knowledge expands. Now with the help of our technical consultant, Dr Nick Welton we are looking at further improvements in project OPTIMA

January 2003 – RoHS Directive 2002/95/EC

Often labelled as the “lead-free directive” but restricted the use of 10 substances in the manufacture of various types of electronics in the European Union. Among the 10 listed substances was hexavalent chrome:

Lead (Pb)

Mercury (Hg)

Cadmium (Cd)

Hexavalent chromium (Cr6+)

Polybrominated biphenyls (PBB)

Bis(2-ethylhexyl) phthalate (DEHP)

Butyl benzyl phthalate (BBP)

Dibutyl phthalate (DBP)

Diisobutyl phthalate (DIBP)

This set a maximum of 1000 ppm (100 ppm for Cd) for homogeneous materials within a product.

December 2006 – WEEE directive 2002/96/EC (UK law)

WEEE stand for Waste Electrical and Electronic Equipment. This directive originally set out a target for the EU member states, for the recycling and recovery of all types of electronics products, of 4 kg per head of person per population by 2009. Although this directive became European law in 2003 it was only transposed into UK law in 2006. The original deadline of transposition to national law of 13 Aug 2003 was only met by Cyprus.

December 2010 – Chromium (VI) compounds added to the REACH SVHC list.

Adding a substance to the SVHC (substance of very high concern list) is the first step in the procedure for the restriction of use of a chemical. The reason for chromium trioxides inclusion is due to its carcinogenic and mutagenic effects.

July 2016 – 15 years chrome free!

Powdertech Surface Science reaches its 15th year of being completely chrome-free! It was also the date we celebrated 15 years of working with JLR.

21st September 2017 – Reach Annex XVII

Sunset date for use of chrome VI industry wide. This is the original date set by the European Commission to ban the use of chrome VI products and is still the official date of final use however, a consortium called CTAC (Chromium Trioxide Authorization Consortium) are seeking to applying for an extension beyond this date for 6 uses of chromium trioxide – particularly in safety critical applications. This would enable the use of chromium trioxide based processes by those supplied directly or indirectly by the 7 applicants at least until a decision by the European Commission is made.

Outlook

In our opinion, any ban on the use of a hazardous substance must be a good thing. The switch to chromium-free systems for pre-treatment isn’t easy but our track record of success shows that it is achievable. Our pre-treatment systems for bonding and powder coating of alloys of magnesium and aluminium, offer industry leading performance. If you need any information on our chrome-free systems please, feel free to contact us.

400,000 Magnesium FECs

Powdertech Surface Science Ltd, experts in lightweight material processing, has blazoned into 2018 by coating its four-hundred-thousandth magnesium front-end-carrier for Volvo cars. The FECs are coated in a bespoke textural polyester powder coating, designed, by Powdertech, for magnesium.

Powdertech pioneered a process of coating the intricate, finely cast magnesium parts in a powder with ‘anti-gassing’ properties. The formulation of the powder allows the release of any gases trapped in the casting during the coating process. This ensures that the powder coated surface is intact, providing the maximum degree of corrosion protection on cast parts.

The textured appearance of the coating was designed to meet an aesthetic requirement for all under-bonnet components to have a homogenous appearance, irrespective of the substrate material.

“We thrive on developing the best processes and materials for coating and bonding light weight materials,” said James Grant, Director, Powdertech. “And our expertise in working with magnesium is a competence we are particularly proud of.”

Call 01869 248218

New, Operations Manager – Matt Goldie.

Please join us in congratulating Matt Goldie on his new position as Operations Manager here at Powdertech Surface Science.

Following Matt’s internal promotion he will have responsibility for the overall operations function, covering all areas of the business, working with everyone to improve our systems and helping to make us a better company going forward.

Matt’s previous role as Production Manager, combined with his in-depth knowledge and experience of the business, makes him the perfect person to guide our operations toward the future and help us manage our continued growth as a company.

Well done Matt and thank you for all your hard work, from the whole team!

Our new powder coating system!

Powdertech Surface Science have invested £0.5 million in a brand new, state-of-the-art powder coating line. We are very excited to announce our new line has completed its commissioning and is now up and running and in full production!

The line is fully automated, embedded with the latest technology and is capable of even higher quality finishes whilst maximising throughput.

We pride ourselves on being able to undertake projects of all sizes and complexity; from 4 metre extruded profiles to sheet and small light fittings to intricate engineered assemblies.

Our new horizontal line represents a step change in our capability which, when coupled with our fully automated vertical line, will help strengthen our already lengthy track record in these areas, making us more efficient at the same time.

We welcome all visitors to come and see the new line in action. Please go to our contact page to schedule a visit or find out more about our capabilities.