Robotics, Space & Satellite

Powder coating for advanced robotic technology

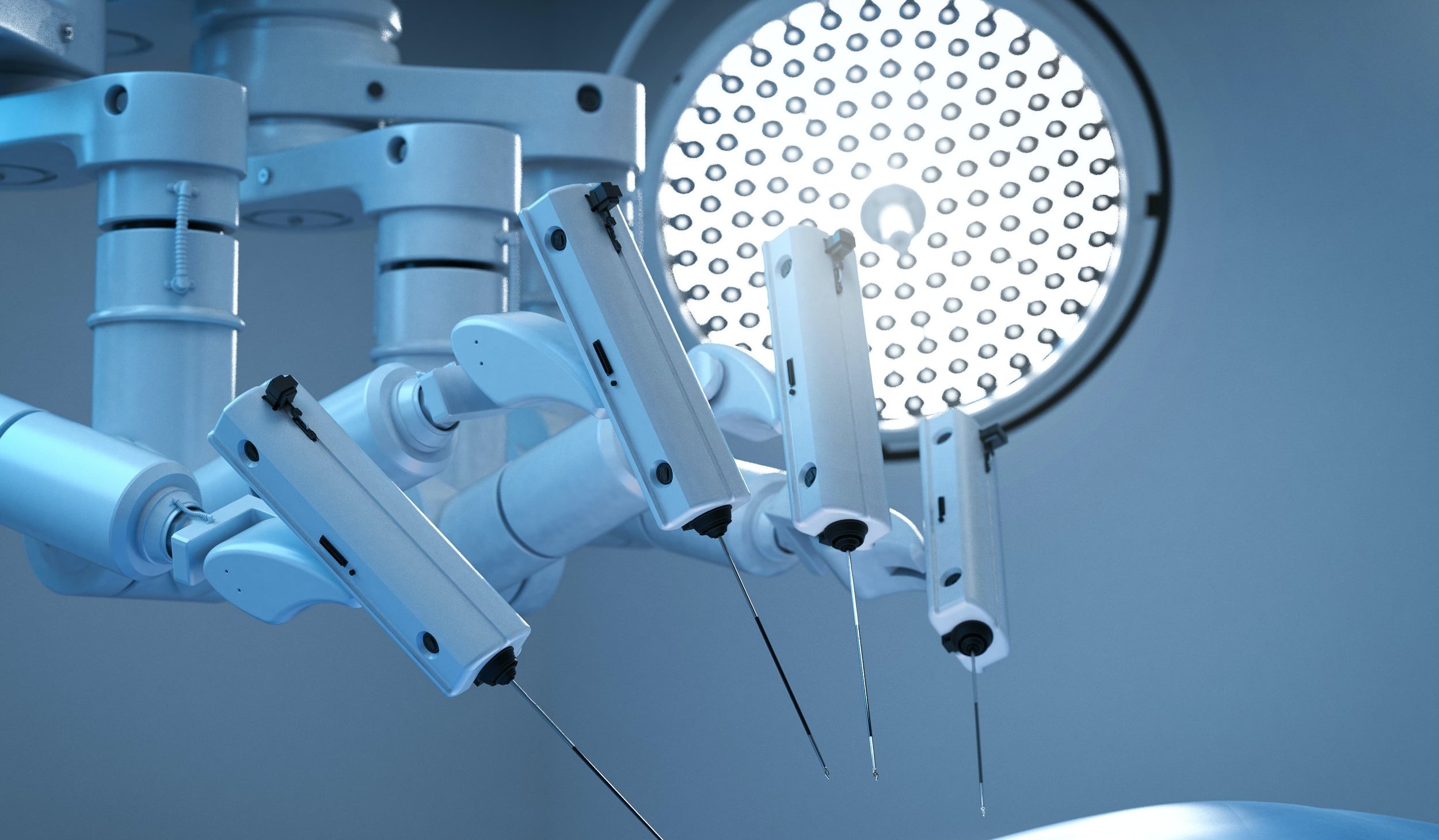

Robotics and AI are making an increasing impact in all areas of our lives. They are powerful tools that can revolutionise how our world operates in so many ways, from manufacturing to medicine, education, logistics, travel and energy conservation. At their best these technologies are facilitating better ways of providing vital services, helping with decision making and moving the world towards a sustainable future.

This equipment is typically composed of small, meticulously formed parts, often extremely delicate. They may need to be used in challenging climatic conditions, at high altitudes or under water. Exacting assembly requirements will tolerate no deviation from precise measurements in dimension, including the thickness of coatings.

“ At full system commissioning and hand over, our own client was blown away by the prototype performance and couldn’t understand how we were able to pull such a high performing system together in such a short time. This was due in no small part to the effort, responsiveness and quality of work from Powdertech. ”

Our expertise in surface coatings for robotics and AI

Our INTRICOAT service was developed specifically for exquisitely designed components with intricate tolerances.

We provides an end-to-service from prototype to full production, all under one roof.

INTRICOAT provides CAD masking schemes involving custom-made die-cut masking kits to prevent coverage in those areas to be left free of coating.

Masking and powder coating for INTRICOAT is carried out in a separate room from the rest of our plant.

All stages of the process receive hands-on attention, control and monitoring.

We are approved applicators for the best quality powder coatings and have many years’ experience in chrome-free conversion coatings and pre-treatments including TiZr and Iridite NCP, frequently specified by regulated industry sectors such as medical.

Enhanced corrosion protection and precision coating for outdoor robotic and surveillance equipment

Robotic and radar technology needs to operate in all environments including desert and coastal/offshore and in all weather conditions, with no deterioration of function. An hermetic seal between the components needs to be achieved making the interior cavity airtight.

Protective treatment of the aluminium used for the radar housing is therefore critical as every surface is important to the integrity of the product and its successful deployment of scanning, recording and disseminating abilities.

The internal surfaces of the housing need to be free of a final powder coating and therefore required an initial pre-treatment with high corrosion resistance such as Iridite NCP.

For application of the topcoat, INTRICOAT detailed CAD masking schemes will ensure that particular areas are kept free of powder as specified by the client.

Robotic and satellite surface treatment case study

Clients in this sector are mostly carrying out work with NDAs attached, including prototype development, so we cannot talk about them. This is one recent project that we can mention.

Can we help with your robotics metal finishing project?

or find out more about INTRICOAT and our powder coating services for aluminium and magnesium

Other Sectors