Resicoat®

AkzoNobel’s dielectric powder coating systems

Resicoat® – The industry‑leading dielectric powder coating from AkzoNobel

What is Resicoat?

Resicoat® is AkzoNobel’s renowned dielectric powder coating brand, originally developed for electrical insulation applications and now a critical component in many electric vehicle (EV) systems. The brand celebrated its 50th anniversary in 2021, having been established by Robert Bosch GmbH and Akzo Coatings GmbH in 1971. In 1992, Resicoat became part of Akzo Coatings GmbH, and has since established a global production footprint.

Resicoat is one of a number of dielectric powder formulations, used by OEMs and specialist powder coating companies like ours to protect EV batteries, busbars, motors, and cooling systems. It has high dielectric strength, UL certification, and chemical resistance, and can be trusted choice for safety, efficiency, and durability.

How Resicoat EV achieves electrical insulation and performance

Resicoat is based on epoxy resin chemistry. Epoxy resins are thermosetting polymers that form a highly cross-linked network when cured. This network:

Prevents the movement of electrons, making it a very effective electrical insulator.

Provides a dense, pore-free coating that resists the ingress of moisture and contaminants.

Resicoat powder is applied using electrostatic spray (ESD) or fluidized bed dipping. After application:

The coated part is baked in an oven, typically at 180–230°C, depending on the product grade.

Heat causes the powder to melt, flow, and chemically cure into a uniform, strongly-adhering coating.

When Resicoat is cured this initiates a crosslinking reaction between the epoxy resin and hardener (usually a dicyandiamide or phenolic). This reaction:

Forms a 3D molecular network.

Results in a rigid, non-conductive, and chemically resistant coating.

Resicoat products

Resicoat coatings are available in two main categories: Resicoat EV for electric vehicles and Resicoat EL for general industrial use.

Resicoat EV range – Electric vehicle applications

Resicoat EVcell

For cylindrical and prismatic battery cells. Offers high dielectric strength, chemical resistance, and excellent edge coverage.Resicoat EVpack

Insulates entire battery packs, covers, and housing systems. Rated UL 94 V‑0 and UL 746B to 130 °C.Resicoat EVcooling

Designed for EV cooling plates and thermal interfaces. Combines insulation with thermal conductivity.Resicoat EVbusbar

Protects busbars made of copper, aluminium, or plated metal. UL 1446 Class F rated with high mechanical durability.Resicoat EVmotor

Suitable for electric motor stators and hairpin windings. Fluidised-bed or spray application. UL 1446 Class F/H.

This is a long-established system for industrial, transformer, and electrical equipment coatings. Different powders in the range are rated to different temperatures and different applications

Resicoat EL3

Epoxy powder, UL 1446 Class F (155 °C), excellent edge coverage

Resicoat EL4

High-temperature epoxy, UL 1446 Class H (180 °C) ratings

Resicoat e‑lock

Epoxy series for slot insulation, enhances protection/durability

Resicoat EL‑LAT

Lower-application-temperature epoxy, improves sustainability and energy saving

Resicoat EL201

UL 94 V‑0, UL 746B, UL 1446 system component certification

Why choose Powdertech for dielectric coating?

Our dielectric coating services use powders that are especially formulated to meet your specification. Sometime this is a Resicoat powder.

Unrivalled experience. We have been fortunate enough to hone our expertise through working with major OEMs and Tier 1 companies in the EV sector. This has provided the opportunity to discover many challenges arising in the application of dielectric coatings and to find the best solutions.

Our in-house testing facilities are fundamental to perfecting our processes and we have invested in the best equipment for the job. We have PhD level expertise on our team and regularly collaborate on international research projects. Testing and development is an essential part of our service offering.

One-coat application efficiency – We deliver accurate film builds in a single pass where possible.

High-voltage performance – We meet or exceed UL electrical insulation and flammability standards.

OEM & tier Supplier Support – We provide full technical assistance from coating trials to production.

At Powdertech, we don’t just apply coatings - we engineer solutions. Our expertise in dielectric science, precision application, and supply chain integration makes us the go-to partner for EV battery and component manufacturers.

To ensure the success of your dielectric powder coating project

Let’s build the future of EV insulation together.

The complete guide to dielectric coating for EV battery assemblies series.

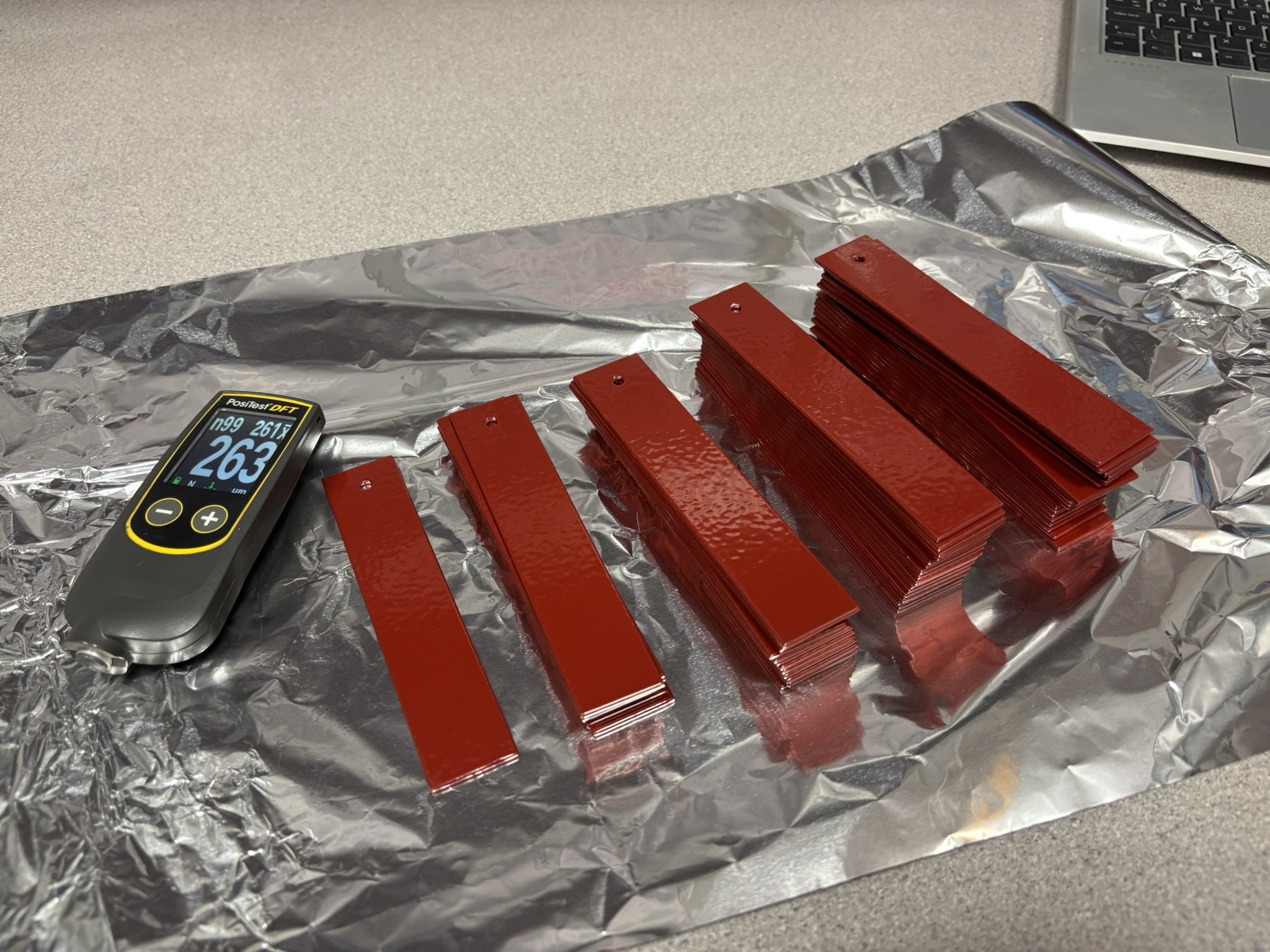

Dielectric coupon testing is a low-risk testing process for validating dielectric coating on aluminium components. These aluminium test coupons would let us simulate how your dielectric coating will perform under read-world conditions, before coating at scale. Read more…..

A minor redution in coating thickness at an edge can lower insulation resistance below acceptable thresholds, leading to electrical arcing, or outright machine failure. Read more….

Porosity in dielectric coating refers to microscopic air pockets, bubbles, or voids that can form within the coating layer, affecting the insulation in EV battery assemblies. Read more…..

More reasons to choose Powdertech metal finishing

We carry out a meticulous final inspection - checking dimensions and visual aspects of the parts.

Direct despatch to OEM’s. We are familiar with EDI systems and online booking of transport, direct to end users.

We offer express turnaround in a matter of hours - we are set up for rapid job completion where necessary.

Dedicated warehouse facilities for raw and finished goods.