INTRICOAT Precision powder coating on magnesium medical robotic parts

Ultra-lightweight magnesium a necessity for this robotic surgery system

Working with a partner on a component for a robotic surgery system, Cambridge Design had found that even lightweight aluminium was too heavy, so acute were the tolerances of the system. This meant that magnesium AZ80 was introduced alongside aluminium alloys. Metals used for medical equipment require powder coating in most instances and this was no exception.

Our powder coating for magnesium service would protect the underlying metal from any corrosive substances or abrasion and provides an easy-to-clean surface.

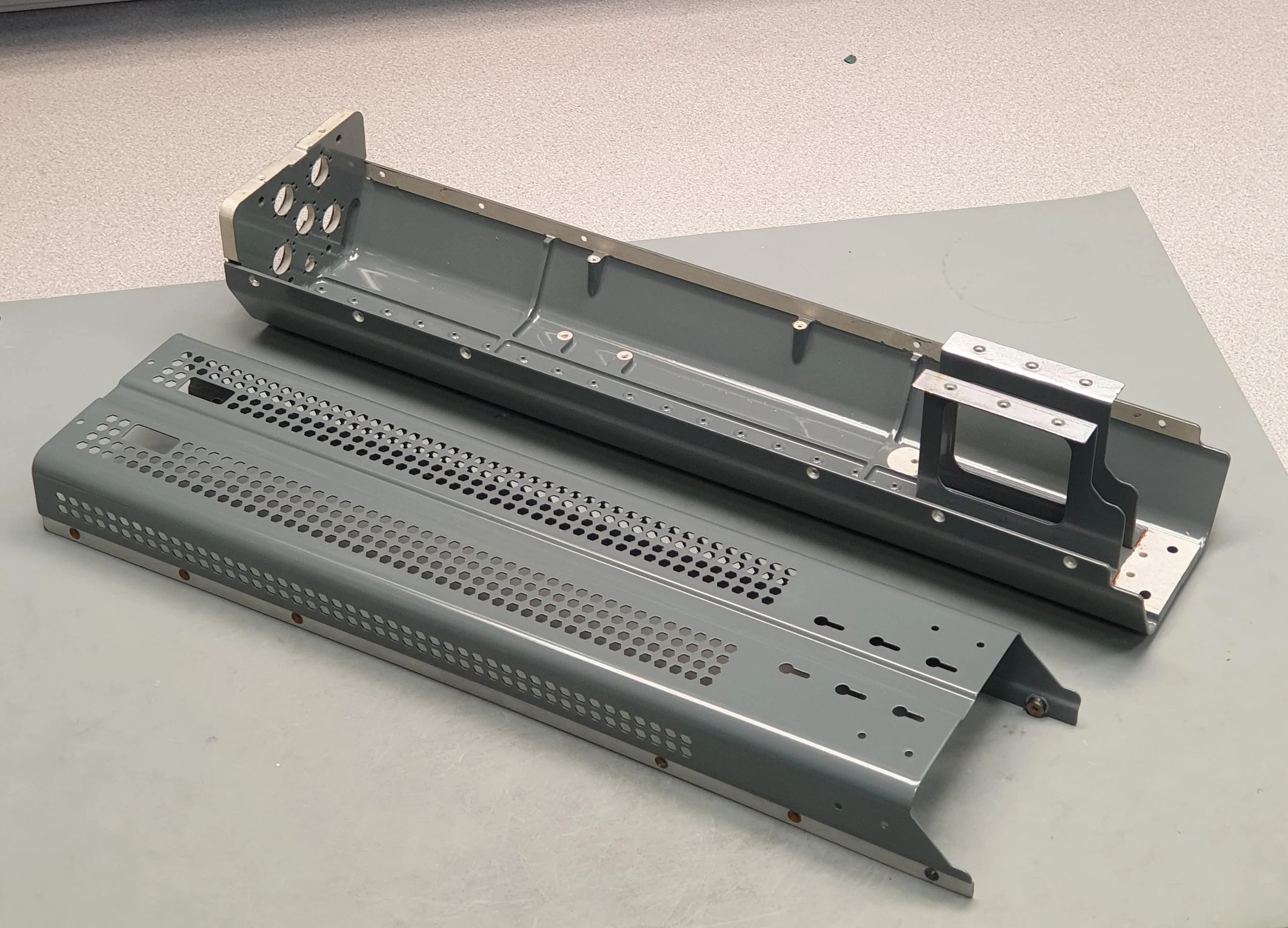

Magnesium components masked for powder coating

Detailed CAD masking schemes reduce the need for prototypes.

It was important that certain areas of the device were left free from powder coating. Solutions for the metal finish had not been specified and therefore the INTRICOAT team could provide technical input for masking scheme design and an optimal coating system. The team studied design drawings received from Cambridge Design and created masking proposals which were easily viewed on 3D CAD and assessed with the client. Our INTRICOAT masking schemes are sufficiently detailed to be viewed on CAD without the need for masked prototypes, saving time and costs for our customers.

Powder coating magnesium

Powdertech Surface Science is very familiar with coating magnesium parts as well as aluminium and has unrivalled expertise in masking procedures for intricate and complex designs. See our INTRICOAT service page.

With the masking scheme agreed, we carried out chrome-free pre-treatment followed by precise custom masking and final coating with a high performance Syntha Pulvin powder coated finish. This all takes place in the dedicated INTRICOAT facility within our plant.

Powder coated component

Masking on magnesium parts

Powder coated magnesium parts

We became a valued partner for the Cambridge Design Partnership on this project and were delighted with the feedback below.

“Hi James and Ian, I just wanted to drop you a quick note to say thanks for all your hard work on our project parts over the last few months. We’ve just completed full system commissioning and hand over and our client has been blown away by its performance. They couldn’t understand how we were able to pull such a high performing system together in such a short time in the middle of all this supply chain madness which is due in no small parts to your efforts, responsiveness and quality of work- so thank you.”

The Cambridge Design Partnership is an innovation partner, assisting global brands and entrepreneurial start-ups from astute ideas to successful production. The teams work across many engineering and scientific disciplines including industry, robotics and healthcare.

Benefits of INTRICOAT - Taking care of every aspect

Your work is in safe, experienced hands

We take responsibility for all aspects of masking and coating so that you can concentrate on critical design and engineering.

The final stage of manufacture, the finish, is generally under time pressure. We understand this and have invested in a dedicated separate facility, located within our plant, to be used exclusively for customers requiring Intricoat services.