Bespoke 3D printed masking: How INTRICOAT precision powder coating designed the perfect finish for MUOV bikes.

“An outstanding partner delivering exceptional consistency and precision from CAD to final finish, INTRICOAT sets a high standard for indoor smart training with exceptional consistency, precision & beautiful technical finish”

Muoverti, high-end indoor smart cycling

Muov bike

The Muoverti Tilt Bike is a unique indoor cycling experience. This lightweight cycling indoor trainer tilts like riding a bike outdoors and enables immersive 3D simulations for training, esports, and interactive fitness.

The inner-workings include an algorithm-driven physics engine that simulates real-world forces such as acceleration, incline, and braking, a digitised handlebar steering and an elastomer-guided side-to-side tilt.

Surface finish required in high-quality aluminium sports components

We are coating the base of the MUOV bike. The base provides the stability for the bike to provide the dynamic experience of cycling & is produced from machined aluminium to ensure the mass and rigidity are in the optimum areas.

A powder coat finish provides a high level of durability to a moving unit and also protects it from the perspiration of the rider.

MOUV in partnership with Powertech

Our INTRICOAT service provided not only precision masking and coating for exceptional aesthetic quality on MUOV’s aluminium components, but we also advised on the most suitable powder coating formulation and colour choice, a metallic dark grey. We ensured to achieve a base that looks good, is durable and performs in the real world.

A long-term partnership, driven to achieve precision in powder coating, bespoke 3D masking and to achieve consistent aesthetic surface finish for their high-end sports product and demonstrator units.

Critical MUOV concern areas; Converting customer challenges to opportunities.

1. To have experience & technical expertise, capability to design a surface finish system that aligns & adapts at the prototype stage to the full production stage

2. To take up the end-to-end ownership of the process to ensure the surface finish process is in alignment with the functionality and visual requirements of the product, ensuring its market ready.

3. In tune with tight prototype production deadlines, for MUOV, producing prototype or demonstration products for shows and exhibitions invariably ends up being a close-to-the-wire exercise.

Collaboration with Powdertech Surface Science for advanced precision powder coating resulted in desired performance and reliability.

Beyond powder coating, on-site technical expertise & bespoke masking in designing the right finish-

At INTRICOAT, we have over 50 years between the team members, making us experienced in providing technical inputs for masking scheme design.

It is the journey from the prototype stage to the production stage. And with INTRICOAT, it is possible to develop a design system to -

Develop prototype masking for proof-of-concept

Refine masking to meet rollout requirements

Finalise masking to meeting high volume production requirements.

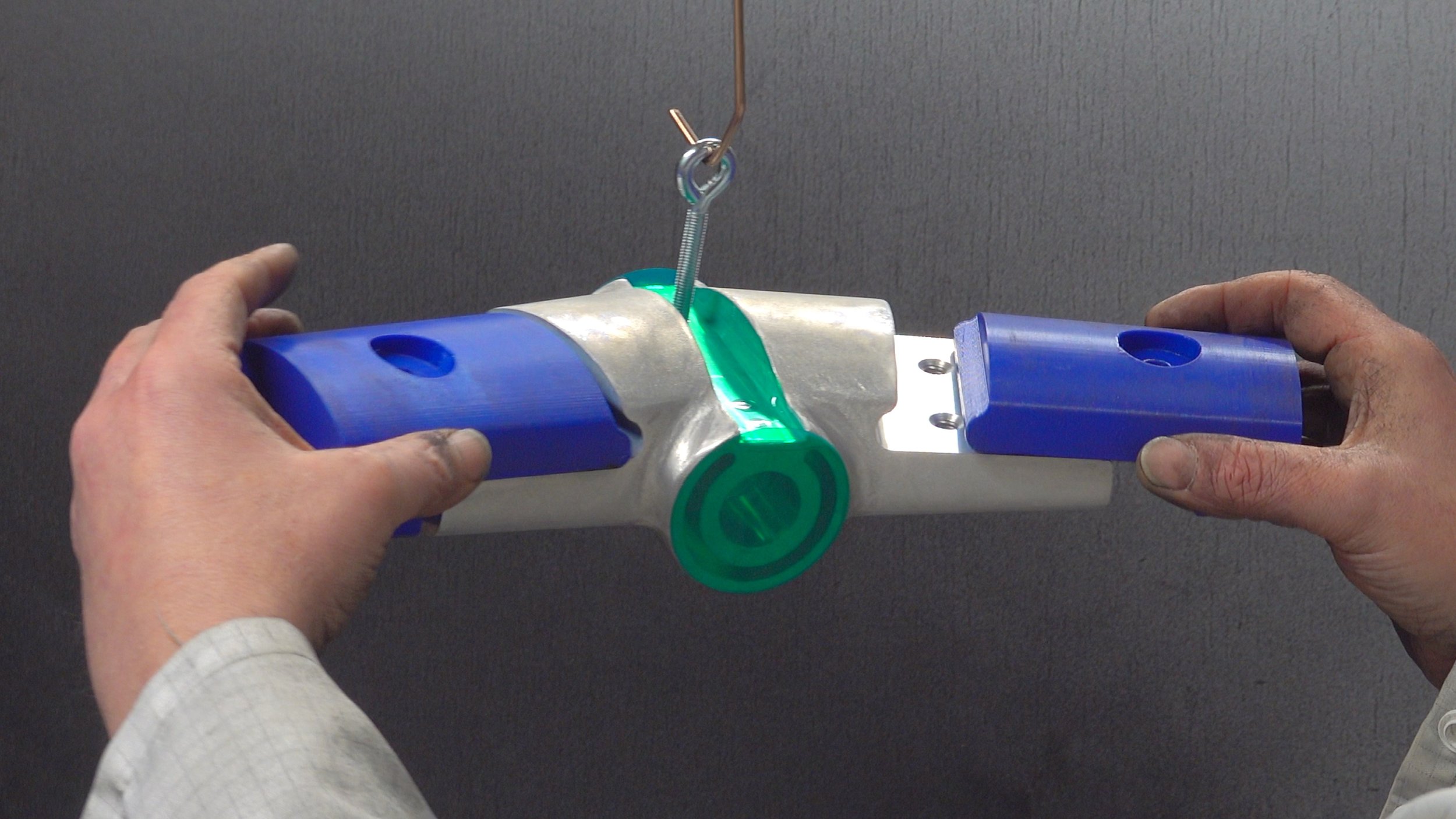

INTRICOAT masking schemes were prepared on 3D-CAD, a mix of die-cut kits and 3D printed removable masks, leaving certain component surfaces free from powder coating.

Muov bike component

2. Avoiding torque relaxation between the part joints-

Bespoke 3D masking kits were placed to avoid powder between the two joints, as it affects the assembly of the parts. Powder within joints can lead to torque relaxation of fasteners, resulting in the joint becoming loose, and in a sports bike, when joints are loose, it creates safety hazards to the rider.

3. Creating a high-quality design system that performs at the prototype stage & ability to adapt solutions for large-scale production -

The benefit of INTRICOAT is moving from prototype to finalised design to creating a masking and coating solution for mass production, making the bike market ready. By developing scalable masking design solutions and fostering long-term customer relationships, we help customers make more informed decisions at the product design stage.

This fuels long-term production scalability as they have a particular set of requirements, and we have the expertise to design the masking, using a mix of different methods to get the best result, and we can then adjust from prototype/small batch in INTRICOAT to mass production on automated lines.

INTRICOAT brings these technicalities together, reducing the need for masked prototypes, saving time and costs for MUOV.

Precision powder coating at Powdertech

4. Faster turnaround times-

The final stage of manufacturing, the finish, is generally under time pressure. We understand this and have invested in a dedicated, separate facility, located within our plant, to be used exclusively for customers requiring INTRICOAT services.

We recognise that our customers operate to tight production schedules. They’re not waiting on coating trials, but on their own manufacturing timelines, so when time and components are limited, we optimise our resources and rely on our team’s expertise to deliver efficient, reliable outcomes.

Hence, we were able to alleviate the pressure during the prototype production stage with our in-house capability to design and implement complicated masking schemes within short timescales and to carry out detailed precision coating to meet MUOV’s requirements.

Have an intricate powder coating requirement?

Connect with us to discuss your precision powder coating project.