How a new bonding solution could be a game-changer for vehicle lightweighting

Dated: Nov 2020

As the spotlight is focussed on the impact CO2 emissions are having on our climate the transport sector in particular has come under intense scrutiny and is being challenged to adhere to the CAFÉ regulations to sustainably reduce emissions from automobiles. Transport is a pivotal sector for achieving EU wide emission targetsi as it accounts for 25% of all EU’s greenhouse gas emissionswith road transport having the largest impact due to the shear number of vehicles in operation.

Current Euro 6 targets stipulate CO2 emissions for passenger vehicles at <95g CO2/km by 2021, with the 2025 targets being ~70g/km. Even with the steps many OEMs have taken, they will miss the legislated 2021 targets, and will be liable to face fines of up to €95/g above the target. From the current average emissions of 118.1g/km, the required reductions of 23.1g/km will require OEMs to lose >230kg/vehicle in the five years

Prioritising lighter weight in vehicle design

Reducing vehicle weight is a critical piece of the puzzle with all manufacturers prioritising this design aspect into future vehicles. Many vehicle OEMs have significantly reduced the weight of their vehicles in recent years, in a bid to achieve the stringent CO2 targets. Over the past 20 years, the industry has shifted from relying predominantly on steel for chassis structures towards increasing use of aluminium, with OEMs such as Audi unveiling entire aluminium models with their 3rd Generation Audi A8 model. Beyond this, further weight optimisations are being sought through the increased use of lightweight materials with composites such as glass-filled and/or carbon fibre in structural applications alongside conventional materials, such as in the BMW i3/i8 and 2017 Audi A8 models (multi-material BIW – aluminium, hs steel, magnesium and CFRP)

However, consumer demand for SUV’s, more integrated functionality, autonomous vehicles coupled with more stringent safety requirements is countering the incremental weight savings that can be achieved and forcing designers to seek more radical solutions.

Thus the industry focus is also on eliminating emissions during the use-phase of a vehicle by replacing the ICE powertrain with EV propulsion systems. A long term strategy of hybrid ICE/EV powertrain being succeeded by plug-in battery powered EV and eventually yielding to fuel cell EV vehicles is anticipated. EV’s do not eliminate greenhouse gas emissions completely when a life cycle analysis of the vehicle is considered including the manufacturing process and electricity generation, however this is anticipated to reduce in the long term as more renewable energy sources come on stream.

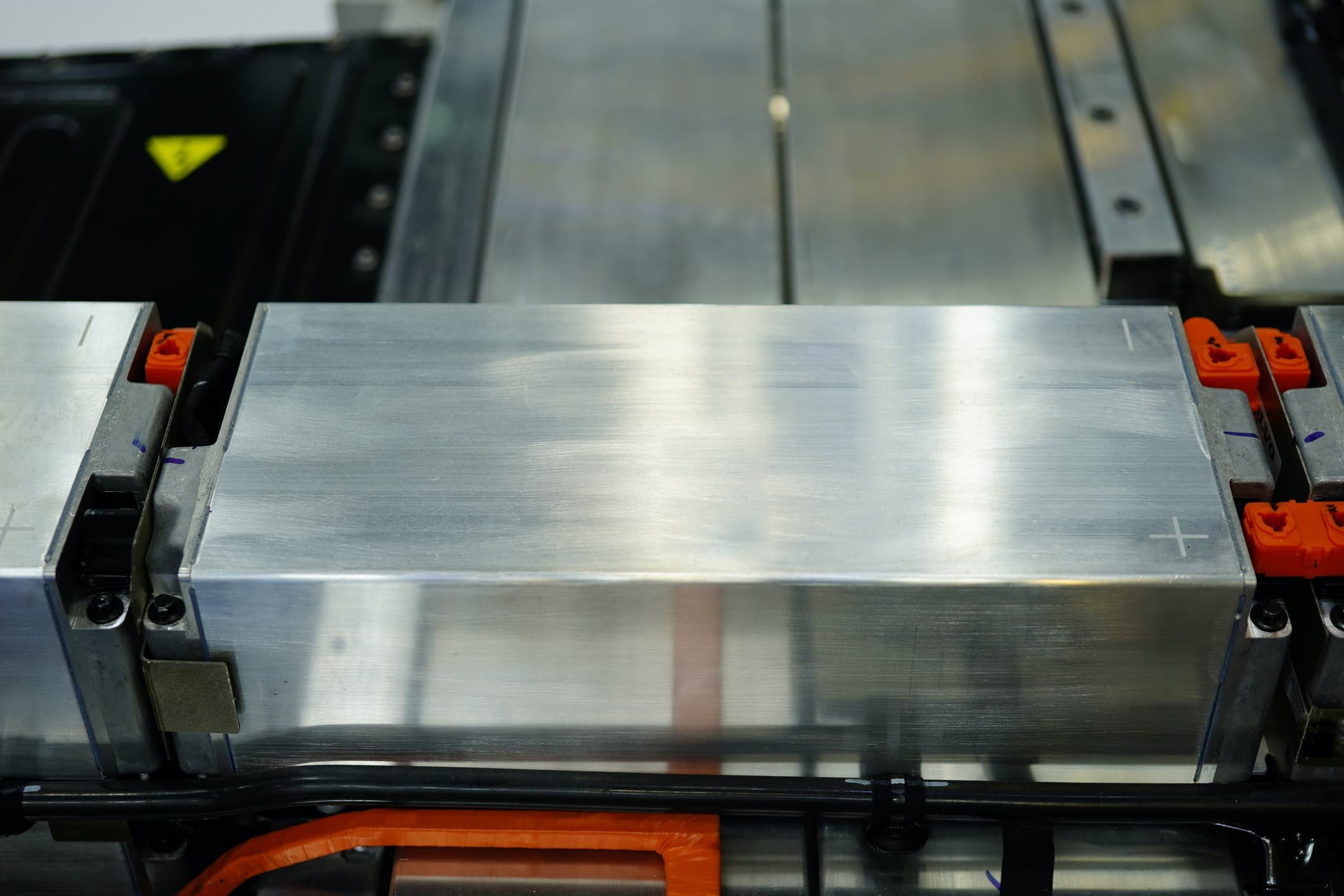

Electrification of vehicles

The move to EV powertrains does not resolve the lightweighting challenge, the technology shift merely alters the benefits being sought by consumers. For cars the priority moves to range between charges and maintaining the mass below a threshold requiring an additional license; in the commercial sector passenger and payload capacity can be maximised by minimising vehicle weight. Battery assemblies are a significant contributor to the weight of an EV powdered vehicle. Lighter vehicles lead to smaller kW demand and lighter batteries reducing the environmental footprint, so there remains a significant incentive to lightweight EV’s.

Materials for vehicle lightweighting

Body in white (BIW), the car body's frame before painting and before the motor, chassis sub-assemblies, or trim have been integrated into the structure, is estimated to hold the largest share of the automotive lightweight material market, by application. BIW comprises of three major parts - passenger compartment, cross and side beams, and front and rear structure and contributes around 27-29% of the total vehicle's curb weight. Hence, it is the primary target for vehicle weight reduction by OEMs. At present, HSS and aluminium are the major lightweight materials used in BIW for maximum weight reduction. Hence, BIW is projected to be the largest segment, by application.

Light-weighting strategies are centred around the philosophy of using the right material in the right place. Two key elements of the process are the use of materials with a high strength-to-weight ratio coupled with smart/intelligent design to maximise the properties and utilisation of the material.

Traditionally this was a two horse race between HS steel and aluminium, but the significant advantages offered by composite materials are being recognised and the outlook is a mixed material approach incorporating more fibre reinforced composite into the structure. Thermoplastic composites are recyclable both in the manufacturing process and at end of life of vehicles and offer numerous additional benefits;

short cycle times

compatible with many processing techniques

thermoformable

weldable

can be over-moulded

offer excellent strength and stiffness to weight ratios

The combination of metallic and composite materials shows a synergistic improvement when combined in plastic metal hybrid structures, with anisotropic UD composites being strategically placed to significantly reduce part weight while increasing stiffness where required.

Bonding of dissimilar materials

However, before materials such as composites can be adopted into mainstream structural applications, some key challenges need to be overcome – primarily the bonding of dissimilar materials (composites, plastics and metals).

A variety of joining processes are currently employed in the bill of process with adhesive bonding being the fastest growing technology to join composite materials. Adhesive bonding offers performance benefits due to the ability to spread loads over large areas, in contrast to mechanical fasteners that create stress concentrations at the weakest point of the material due to fibre breakage resulting from insertion of the fastener. Due to creep behaviour of certain polymeric materials torque relaxation can present an additional challenge for mechanical fasteners.

It is estimated that there are in excess of 250,000 grades of adhesive available from over 1000 suppliers (REF TWI REVIEW) yet still there remains a significant challenge to achieve structural bond strengths on low surface energy polymers (LSE).

Polypropylene – excellent credentials but averse to adhesives

LSE surfaces are typically apolar and include binder polymers such as polypropylene. The low cost, wide availability, good processability, hydrophobicity and excellent chemical resistance of polypropylene make it a desirable material for lightweight composites. With a wide variety of fibre reinforcements available, including the more commonly used Eglass and carbon fibre, the material is available in a large variety of forms including co-woven fabric, consolidated sheet, injection moulding granules. Although there are adhesives designed to adhere directly to polypropylene, they do not offer structural bond strengths, particularly in wet environments. Prior to adhesively bonding this class of polymer it is common to functionalise the surface to raise the surface energy improving wettability and adding anchor sites onto which structural epoxy type adhesives can grab.

The methods used to functionalise the surface are accompanied by necessary health and safety measures which add additional complexity, time, cost and resource to the manufacturing operation. There is an open time limitation of the functionalisation which generally necessitates an in-line process adding a considerable footprint to the line. The resulting bond strength is often much lower than achieved on metallic surfaces, even after surface functionalisation, and often falls below specification requirements.

Quest for a solution to mixed material joining

To date, the lack of a satisfactory joining solution has deterred designers from specifying PP based composite materials and more expensive materials are often employed to bypass the complexity of the joining process. The determination to use GF-PP in multi-material structures within a collaborative research project drove the development of a new, adhesive-free joining process that enables the design of PP metal hybrid assemblies. This process, named and patented as PowderBondPP, useslean manufacturing principles and delivers exceptionally strong bonds. PowderBondPP can be accommodated into a range of forming techniquesincluding compression moulding, injection/overmoulding, induction bonding and vac-bag moulding.

Lap shear strength of PowderBondPP

Typical failure modes of substrate

One of the key benefits PowderbondPP delivers is unrivalled bond strength between PP and metals in hybrid structures. Mechanical testing of standard joints reveals the peak load on lap shear approaching that of traditional epoxy based adhesives used in metal to metal joints. In fact the common failure mode was cohesive failure of the parent material, with fibre breakage and inter-ply cleavage witnessed for GF-PP composite materials. Having dual functionality, being a corrosion resistant coating system, leads to high bond strength retention following exposure to aggressive environmental conditions including corrosive, wet and humid atmospheres. The durability of the joint has been demonstrated through fatigue testing with full retention of joint strength following 100,000 cycles of HCF. The system can also act as a galvanic isolator when the composite is reinforced with carbon fibre

Lean manufacturing

PowderBondPP delivers far reaching benefitswhich impact upon manufacturing systems. No pre-treatment of the composite surface is required, no adhesive application and no extended cure time. The PowderBondPP system is applied to the metal component which is then heat-fused to the polypropylene in a variety of processes mentioned previously, making the process a rapid joining solution. The technology delivers a repeatable joint performance, essential for many applications.

Design Benefits

Using PowderBondPP reduces part count, improves NVH and enables lightweighting of structures, opening up new design possibilities for plastic-metal hybrid structures by removing the need to incorporate joining features into components. The ability to enclose metallic components within the composite yields both strong and stiff structures and allows the designer to use the right material in the right place, removing the restrictive consideration of how the parts will be post-joined.

Use in a moulded design

Stalcom Automotive exploited the design benefits during the construction of its concept single seater, last mile delivery vehicle with the construction of mixed material sub-structures. PowderbondPP treated aluminium profiles were inserted into the compression moulding tool and bonded to pre-consolidated GF-PP sheet in a single operation. Upon removal from the tool the component had developed its full strength and proved to be a robust component with excellent torsional stiffness. The technology facilitated design experimentation with a series of different geometry junctions being explored allowing the manufacture of complex shapes in a single stage process.

Stalcom PowderBond bonded chassis

Potential of PowderBond in fastening systems

For metal to PP joining purposes outside of moulding techniques, the excellent tensile bond strength, six timesthat of a plasma treated / 2 K epoxy structural adhesive control system, makes the system particularly suitable for the application of metallic fasteners to PP based composite materials. This feature is being evaluated by bighead Bonding Fasteners as it looks to extend its own Lean Bonding® process capability to join metal fasteners to polypropylene, the most widely used thermoplastic material. The two technologies have a natural synergy and the collaboration looks specifically at creating strong reliable bonds with a simple, customer-ready process. The process is compatible with automated application lines and the removal of the need to functionalise the composite surface makes this a very attractive proposition.

Necessity is the mother of invention – and innovation

The previous inability to reliably bond PP, the most cost-effective thermoplastic, to metal, has certainly presented a stumbling block in affordable lightweight vehicle design. PowderBondPP opens up the field again, bringing far more freedom in design and with that, a wide range of exciting possibilities for new vehicles. Necessity has always driven invention and the need to redesign the vehicles on which we all rely, in order to reduce CO2 emissions, is now so urgent and overwhelming that new enabling technologies should be evaluated and adopted wherever possible, and sooner rather than later.

Joining mixed materials in automotive light weighting

References

About the Author

Dr Nick Welton

Technical Consultant

Powdertech Surface Science

October 2022

Nick is a PhD polymer scientist with 24 years industrial experience in the field of polymers and coatings. Nick’s expertise includes powder coatings, material characterisation, specification testing, corrosion, weathering and failure analysis.