Our optimised TiZr pre-treatment ensured secure aluminium adhesive bonding in a bonded aluminium platform.

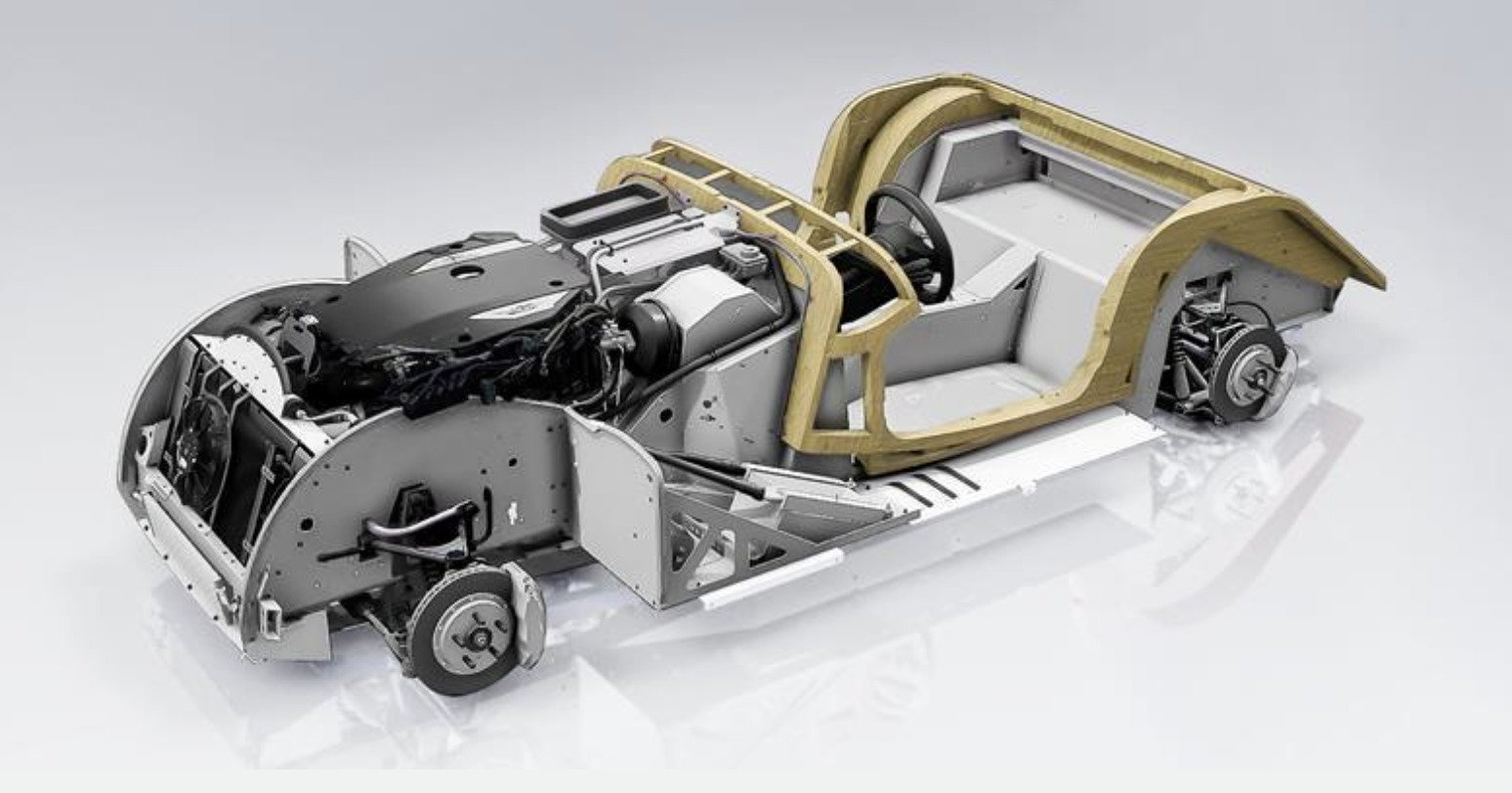

The new Morgan Plus Six

Morgan’s CX Generation bonded aluminium and ash platform is assembled at Fablink’s Brixworth site. A total of 160 component parts make up the chassis, held together using a heat cure adhesive and over 1000 structural mono-bolts and self-piercing rivets, along with 450 threaded inserts.

TiZr pre-treatment creates a stable surface for strong repeatable bonds

In order to enhance the durability of the heat cured adhesive, Powdertech Surface Science applies an optimised titanium zirconium (TiZr) coating to the numerous aluminium extrusions and turned parts. TiZr passivation creates a stable surface which will allow bonding and welding processes to deliver repeatable, strong, durable adhesive bonds. This conversion coating process also provides a stable base for powder coating and offers additional protection against corrosion.

Extensive testing shows that the stable, protective passivation layer achieved through Powdertech TiZr matches the performance of anodising for durability of adhesive joints. TiZr pre-treatment has a faster lead time than anodising, uses less energy and is a more cost-effective and environmentally appropriate process than anodising.

With extensive experience in TiZr technology we are able to give advice to clients on a project by project basis.

The passivation process is achieved in a ten-stage PLC controlled immersion treatment process in which the aluminium surface is cleaned and etched, removing the existing oxide deposit and converting it to a consistent TiZr oxide layer suitable for the adhesive to bond very firmly (see our TiZr page). The end result is an incredibly strong, rigid and lightweight structure weighing less than 100kg.